For inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.

E-TPU Safety Footwear: Advanced Cushioning and Comfort From a Manufacturer’s Perspective

E-TPU Safety Footwear: Advanced Cushioning and Comfort From a Manufacturer’s Perspective

How E-TPU Cushioning Reduces Fatigue in Safety Shoes A Manufacturer’s Perspective

How E-TPU Cushioning Reduces Fatigue in Safety Shoes A Manufacturer’s Perspective

E-TPU Safety Shoes and EN ISO 20345 /Balancing Comfort and Protection

E-TPU Safety Shoes and EN ISO 20345 /Balancing Comfort and Protection

S3 vs S7 Safety Shoes: What's the Difference in EN ISO 20345:2022?

S3 vs S7 Safety Shoes: What's the Difference in EN ISO 20345:2022?

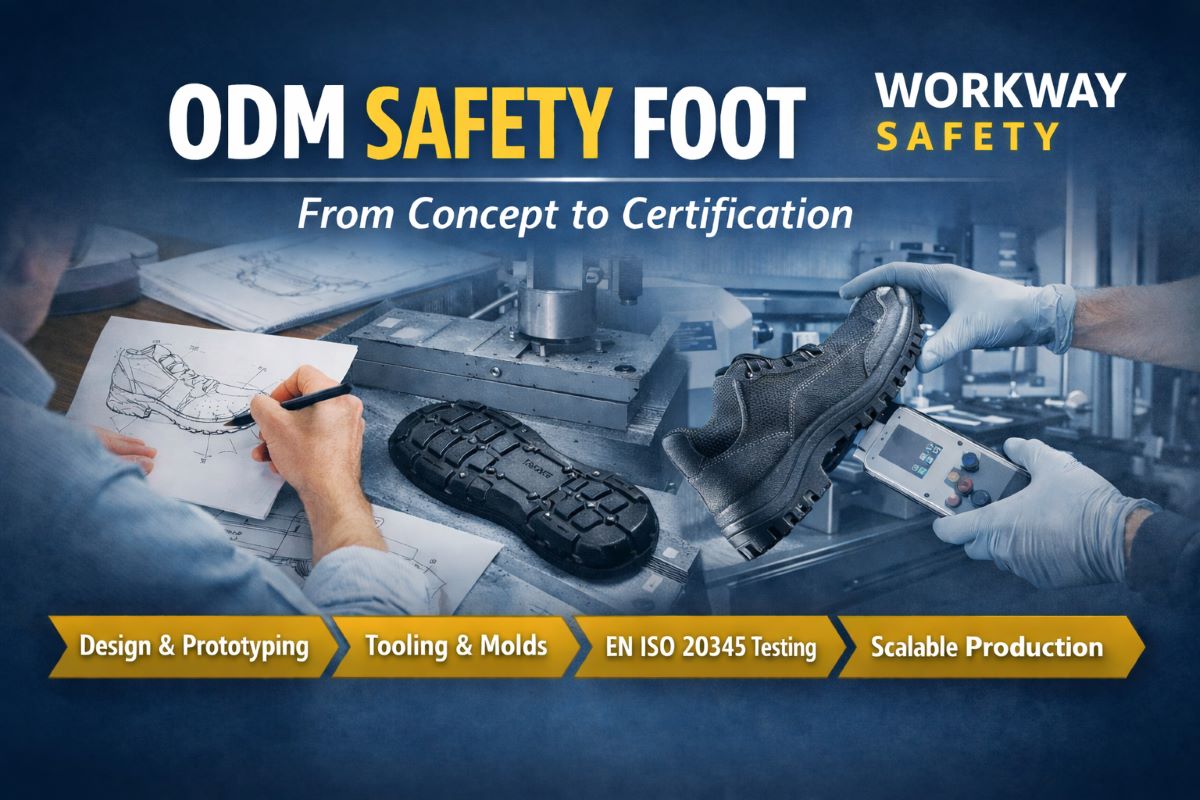

ODM Safety Footwear Manufacturer | From Concept to Certification

ODM Safety Footwear Manufacturer | From Concept to Certification

Why Original Design Matters in Safety Footwear – and How It Benefits Our Global Partners

Why Original Design Matters in Safety Footwear – and How It Benefits Our Global Partners

Safety Overshoes vs Safety Shoes: Which Is the Right Choice for Visitors?

Safety Overshoes vs Safety Shoes: Which Is the Right Choice for Visitors?

Step Up Your Workday: Introducing Our Superior Safety and Occupational Footwear Collection

Step Up Your Workday: Introducing Our Superior Safety and Occupational Footwear Collection

What Are Safety Overshoes? | CE-Certified Visitor Protection by Workway Safety

What Are Safety Overshoes? | CE-Certified Visitor Protection by Workway Safety

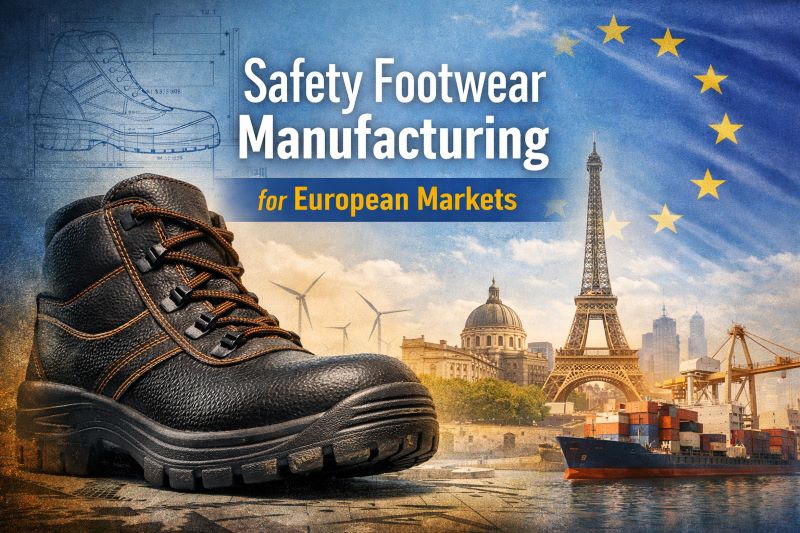

Safety Footwear Manufacturing for European Markets

Safety Footwear Manufacturing for European Markets

Meet Us at Booth 13E12-2 at A+A Fair 2023: Xiamen Workway Protection's Innovative Showcase

Meet Us at Booth 13E12-2 at A+A Fair 2023: Xiamen Workway Protection's Innovative Showcase

Embracing the Trend: Lightweight, Comfortable, Sporty, and Innovative Safety Shoes

Embracing the Trend: Lightweight, Comfortable, Sporty, and Innovative Safety Shoes

1504, Building B, Taidi Haixi Center, Hai Cang District, Xiamen, 361026, China.

1504, Building B, Taidi Haixi Center, Hai Cang District, Xiamen, 361026, China. Jack

Jack Tel: +86-592-6511408

Tel: +86-592-6511408 Email: info@workwaysafety.com

Email: info@workwaysafety.comFor inquiries about our products or pricelist, please leave to us and we will be in touch within 24 hours.