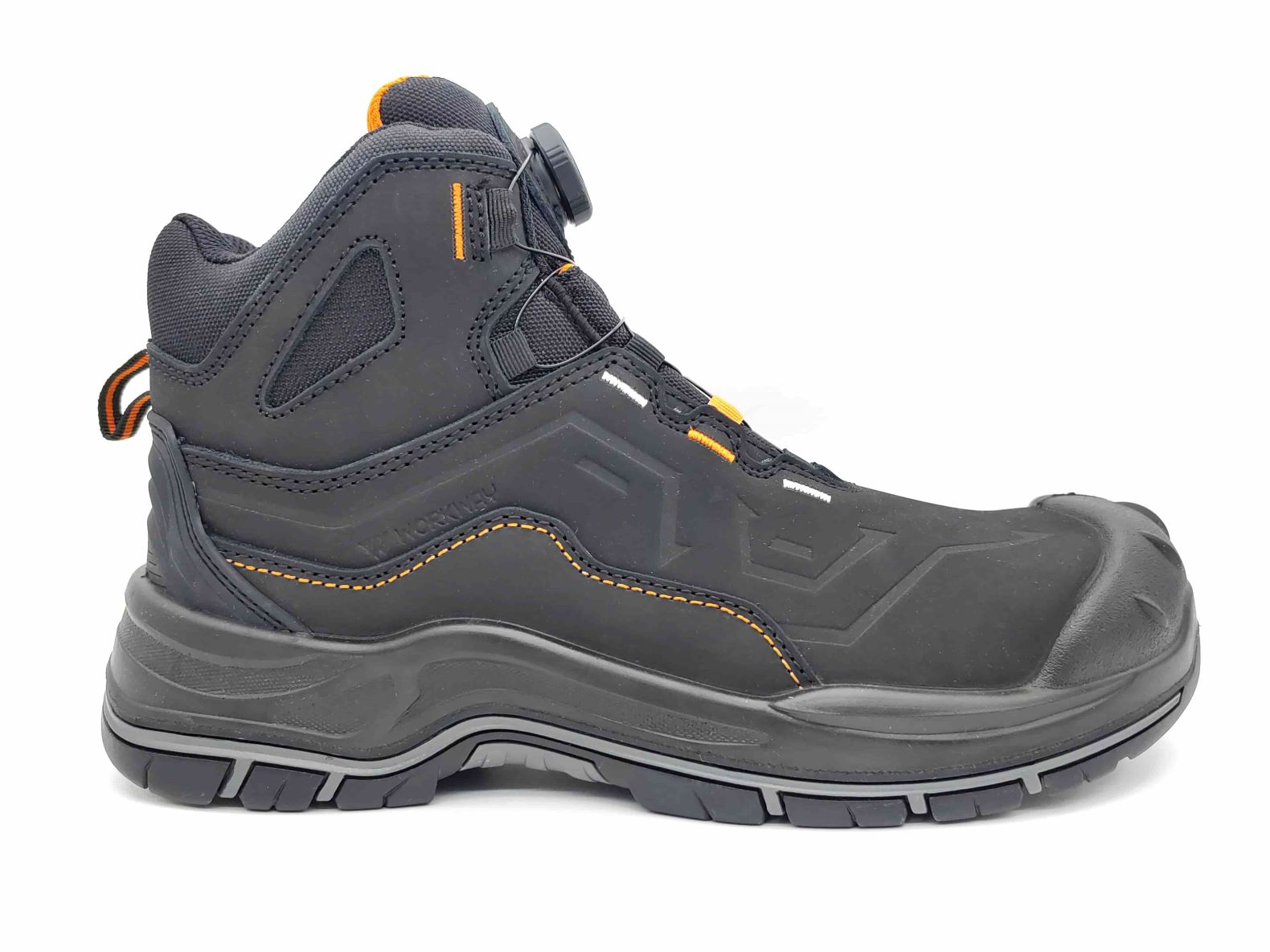

Discover the innovative technology behind Xiamen Workway's new range of Outdoor Waterproof Hiking Boots – designed for durability, comfort, and unmatched performance in rugged terrains. Introduction: In the realm of outdoor exploration, the right gear is not just an accessory; it's a necessity. Xiamen Workway Protection Technology Co., Ltd. is proud to unveil a groundbreaking addition to our product line – the Outdoor Waterproof Hiking Boots, meticulously engineered for the modern adventurer and the professional hiker. A New Era in Hiking Footwear Our latest range of High-Quality Waterproof Hiking Boots for Rugged Terrain represents a significant leap in outdoor footwear technology. Designed with the needs of our B2B clients in mind, these boots are not just a product; they are a testament to our commitment to innovation, quality, and the spirit of adventure. Cutting-Edge Waterproofing Technology Understanding the diverse challenges of outdoor environments, we have integrated both static and dynamic waterproofing technologies into our boots. Static Waterproofing Excellence Our Eco-Friendly Durable Waterproof Hiking Footwear undergoes rigorous static waterproof testing, ensuring they remain impenetrable in wet conditions, a feature highly valued by our B2B partners and their customers. Dynamic Waterproofing for Active Use In addition to static testing, our Advanced Grip Waterproof Hiking Boots for Slippery Trails are subjected to dynamic waterproof testing, guaranteeing performance and protection during active use, making them ideal for challenging outdoor activities. Unparalleled Comfort and Style We believe that comfort and style are paramount. Our Comfortable and Stylish Waterproof Hiking Boots for Outdoor Enthusiasts are crafted to provide exceptional comfort, ensuring they meet the high standards expected by our B2B clients and their end-users. Join the Outdoor Revolution As we gear up for the launch of our Outdoor Waterproof Hiking Boots, we invite our B2B partners to join us in redefining the outdoor gear market. Our commitment to quality, innovation, and customer satisfaction positions us as the ideal partner for businesses seeking to elevate their outdoor and hiking product offerings. Xiamen Workway Protection Technology Co., Ltd. is at the forefront of outdoor footwear innovation. Our new range of waterproof hiking boots is more than just a product – it's a promise of quality, durability, and a passion for the great outdoors. Stay tuned for our official launch and be ready to step into a new era of outdoor exploration. For detailed product specifications, bulk order inquiries, or partnership opportunities, visit our website at WWW.WORKWAYSAFETY.COM or contact us at info@workwaysafety.com.

View More

Jack

Jack